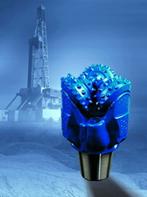

PDC DRILL BIT

Features: 1. Multiple types of high performance PDC cutters are strategically arranged on the bit for improved service life of the bit.

2. Cutting structure is force balanced, bit blade is asymmetrically designed, and spiral blade and spiral gage are also designed so that the load on bit is balanced that resulting better stability of the bit.

3. Optimally designed bit profile for drilling soft to medium hard formations.

4. Hydraulic system of the bit is optimized using CFD technology to enhance cleaning and cooling effects of the bit as well as the ability to effectively prevent bit from balling.

5.Erosion on bit surface is effectively prevented by utilizing hardfacing material of highly erosion resistant and applying advanced base metal enhancement technology.

6. Ports on bit are also optimally designed to prevent erosion of water courses inside the bit.

7. Up-reaming features are also designed to make the bit more suitable for various drilling processes.

Bit size: ―――――――――――――――――8 1/2

Blade count :―――――――――――――――――5

Main cutter size:――――――――――――Φ19mm

Number of nozzles:――――――――――――――5

Gage length:―――――――――――――――64mm

Junk slot area (in2):――――――――――――19.26

Connection:――――――――――――4 1/2 API Reg.

Make up torque (KN.m):――――――――16.6-23.7

Recommended drilling parameters:

Rotary speed(rpm):―――――――――――――――――60-260

WOB(KN): ―――――――――――――――――25-100

Flow rate(L/s):――――――――――――――――――22-35 HJ series bit for oil well drilling

A. Main structure features 1. High precision journal bearing with two thrust faces. Hardfaced head bearing surface. Cone bearing inlaid with friction reducing alloy and then silver-plated. The load capacity and seizure resistance of the bearing is greatly improved.

2. Precise metal face sealed. The two dynamic axial sealing rings of the sealing system are metal seals, and two highly elastic rubber energizers are seated separately in head and cone sealing areas functioning as static seals. Optimized sealing compression ensures good contact between the two metal sealing faces at all times. 3. Ball locked cone, suitable for high rotary speed. 4. All rubber compensator is used which can limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication. 5. New type of wear resistant grease that can sustain high temperature up to 250°C is utilized. 6. High wear resistance and excellent cutting ability of the insert bit are given full play by using carbide compacts of high strength and high toughness in combination with optimized compact numbers and rows, the exposure height and special shaped compacts. For steel tooth bit, the tooth surface is hardfaced with new type of wear resistant material and thus extended working life of the cutting structure while still maintaining high ROP. B. Product predominanceHJ series bit uses the most advanced sealing technology of the world, i.e. the metal face seal (MFS). It can perform consistently in high speed drilling applications, and is the ideal tool for drilling directional and horizontal wells. In comparison with conventional rubber O-ring sealed bits, the average working life (total drilling hours) of HJ series bit under the condition of the same operating parameters can be increased by 35%. C. Available sizes and types of HJ series tri-cone bits Bit size | Bit type | API Regular Pin

(in) | Recommended make-up torque for bit shank(KN.m) | Inch (in) | Metric (mm) | 8 3/8 | 212.7 | HJ437GL、HJ517GL、HJT517GL、HJ537GL、HJT537GH | 4 1/2 | 16.3~21.7 | 8 1/2 | 215.9 | HJT117、HJT137、HJ417、HJ437、HJT447G、HJ517G、HJT517GL、HJS517G、HJ537G、HJT537GH、HJS537GL、HJ547G、HJ617G、HJT617GH、HJ627G、HJ637G、HJT637GH、HJ737G、HJT737GH | 8 3/4 | 222.3 | HJT117、HJT517G | 9 1/2 | 241.3 | HJ437、HJ517G、HJT517GL、HJ537G、HJT537GL、HJ617G、HJT617GH、HJ637G、HJT637GH | 6 5/8 | 37.9~43.3 | 9 5/8 | 244.5 | HJ537G | 9 7/8 | 250.8 | HJT117、HJ417、HJ437 | 10 5/8 | 269.9 | HJT127、HJT137、HJT517G | 12 1/4 | 311.2 | HJ117、HJT117G、HJ127、HJT127G、HJ137、HJ417、HJ437、HJ517G、HJS517G、HJ537G、HJS537G、HJ617G、HJ637G、 | 17 1/2 | 444.5 | HJ517G、HJ527G、HJ537G | 7 5/8 | 46.1~54.2 |

Note: Bit sizes (from 7-7/8″to 17-1/2″) and types that are not shown in above table can be customized according to specific drilling requirements. For insert bit, special T and S features and optional features H, Y, L, G and C can be added. For steel tooth bit, optional features T, L, G and C can be added to the bit. D. Recommended operating parameters of HJ series roller cone bits Bit type | Normal WOB

kN/mm

(bit dia.) | Rotary Speed (rpm) | Cutting structure | Applicable formation | HJ117 | 0.30~0.90 | 300~80 | Hardfaced gage and all tooth surfaces, and the gage fitted with compacts for enhanced gage protection | Very soft with low compressive strength and high drillability, such as soft shale, clay and salt bed, etc. | HJ127 | 0.30~0.90 | 300~80 | Hardfaced gage and all tooth surfaces, and the gage fitted with compacts for enhanced gage protection | Soft with low compressive strength and high drillability, such as shale, clay, salt bed and soft limestone, etc. | HJ137 | 0.35~0.90 | 300~80 | Hardfaced gage and all tooth surfaces, and the gage fitted with compacts for enhanced gage protection | Soft to medium soft with low compressive strength or soft with harder stringers, such as hard shale, soft limestone and sandstone, etc. | HJ417 | 0.35~0.90 | 280~70 | Large radius offset crested scoop compacts in inner row, wedge compacts in outer row, high compact exposure and inequable spaced compacts arrangement | Long section of soft formation with low compressive strength and high drillability, such as shale, clay, sandstone and chert, etc. | HJ437 | 0.35~0.90 | 280~60 | Large radius offset crested scoop compacts in inner row, wedge compacts in outer row, high compact exposure and inequable spaced compacts arrangement | Very soft with low compressive strength and high drillability, such as shale, clay, sandstone, soft limestone, salt bed and gypsolyte, etc. | HJ447G | 0.35~1.00 | 240~60 | Large radius offset crested scoop compacts in inner row, wedge compacts in outer row, high compact exposure and inequable spaced compacts arrangement | Soft with low compressive strength and high drillability, such as shale, clay, sandstone, soft limestone, salt bed and gypsolyte, etc. | HJ517G | 0.35~1.05 | 240~50 | Large radius offset crested scoop compacts in inner row, wedge compacts in outer row, high compact exposure and inequable spaced compacts arrangement | Soft with low compressive strength and high drillability, such as shale, clay, sandstone and soft limestone, etc. | HJ527G | 0.35~1.05 | 240~50 | Large radius offset crested scoop compacts in inner row, wedge compacts in outer row, high compact exposure and inequable spaced compacts arrangement | Soft with low compressive strength and high drillability, such as shale, clay, sandstone and soft limestone, etc. | HJ537G | 0.50~1.05 | 220~40 | Large radius offset crested scoop compacts in inner row, wedge compacts in outer row, high compact exposure and inequable spaced compacts arrangement | Medium soft with low compressive strength and harder abrasive stringers, such as hard shale, hard gypsolyte, soft limestone, sandstone and dolomite with stringers, etc. | HJ547G | 0.50~1.05 | 220~40 | Large radius scoop compacts in inner row, wedge compacts in outer row and inequable spaced compacts arrangement | Medium soft with low compressive strength and harder abrasive stringers, such as hard shale, mudstone, soft limestone and sandstone, etc. | HJ617G | 0.50~1.05 | 220~40 | Large radius scoop compacts in inner row, wedge compacts in outer row and inequable spaced compacts arrangement | Medium hard with high compressive strength and thick & hard stringers, such as limestone, hard shale, mudstone and sandstone, etc. | HJ627G | 0.50~1.05 | 200~40 | Conical compacts in inner row, spherical compacts in outer row | Medium hard with high compressive strength and hard stringers, such as limestone, hard sandy mudstone and sandstone, etc. | HJ637G | 0.50~1.10 | 200~40 | Conical compacts in inner row, spherical compacts in outer row | Medium hard with high compressive strength and abrasiveness, such as limestone, dolomite and hard sandstone, etc. | HJ737G | 0.50~1.20 | 200~40 | Large radius conical compacts in inner row, spherical compacts in outer row | Hard formation with high abrasiveness, such as hard limestone, dolomite, hard sandstone and chert, etc. |

Note: The upper limits of WOB and RPM recommended in above table should not be used simultaneously. Series codes of tricone bits: | Serial No. | Main features of the bearing and seal | Standard series | T (Special gage protection) | 1 | Rubber O ring sealed journal bearing | H | HT | 2 | Rubber O ring sealed improved journal bearing | HA | HAT | 3 | Metal rings sealed journal bearing | HJ | HJT | 4 | Rubber O ring sealed roller bearing | G | GT |

Additional features: | explanation of letter | C | Center jet | L | L-pads | E | Extended nozzle | D | Diamond guage protection | G | Guage protection | SP | Horizontal well |

Tricone Bit Characteristics: | High ROP | Safety and reliability | Extended bearing life | Superior pricing |

HA series bit for oil well drilling

A. Main structure features

1. Journal bearing. Hardfaced head bearing surface. Cone bearing inlaid with friction reducing alloy and then silver-plated. The load capacity and seizure resistance of the bearing is greatly improved. 2. O ring seal is made of the more wear resistance high saturated buna-N with the increased seal section and precisely designed sealing flange in the cone sealing area increased the reliability of the seal. 3. The bit bearing can be ball locked or ring locked. Bit with ring lock bearing can stand high weight on bit and bit with ball lock bearing can be applied to high rotary speed drilling. 4. All rubber compensator is used which can limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication. 5. New type of grease that can sustain high temperature up to 250°C is utilized. 6. High wear resistance and excellent cutting ability of the insert bit are given full play by using carbide compacts of high strength and high toughness in combination with optimized compact numbers and rows, the exposure height and special shaped compacts. For steel tooth bit, the tooth surface is hardfaced with new type of wear resistant material and thus extended working life of the cutting structure while still maintaining high ROP. B. Product predominance HA series bit is O-ring sealed journal bearing product. It can sustain higher WOB under normal rotary speed and is suitable for drilling formations from very soft to very hard by properly selecting different cutting structures. C. Available sizes and types of HA series tri-cone bits Bit size | Bit type | API Regular Pin

(in) | Recommended make-up torque for bit shank(KN.m) | Inch (in) | Metric (mm) | 4 5/8 | 117.5 | HA126、HA216、HA517 | 2 7/8 | 8.1~9.5 | 4 3/4 | 120.7 | HA216、HA517G、HAT517G、HAT537G、HAT627G | 5 7/8 | 149.2 | HA116、HA126、HA136、HAT217、HA437、HA517G、HA527GY、HA537G、HA617G、HAT617G、HA637G | 3 1/2 | 9.5~12.2 | 6 | 152.4 | HA116、HAT126、HAT127、HA136、HAT137、HA216、HAT217、HA427、HA437、HA517G、HA537G、HAT537G、HA617G、HAT617G、HA637G、HA727G | 6 1/8 | 155.6 | HAT117、HAT127、HA136、HAT137、HA216、HA217、HAT217、HA517G、HA527GY、HA537G、HAT537G、HA547GY、HAT547G、HA617G、HAT617G、HAT627G | 6 1/4 | 158.8 | HA116、HA117、HAT117、HA126、HAT126、HA127、HAT127、HA217、HAT217、HAT437、HA517G、HAT517G、HAT537G、HA547GY、HA617GY、HAT637G | 6 1/2 | 165.1 | HA116、HA136、HA137、HA217、HA437、HA517G、HA537G、HA617G、HA637G、HA737G | 6 3/4 | 171.5 | HA547G | 7 1/2 | 190.5 | HA537G、HA617G | 4 1/2 | 16.3~21.7 | 7 7/8 | 200.0 | HA116、HA117、HAT117G、HA127、HAT127G、HA216、HA217、HA427、HA437、HA447G、HA517G、HA527G、HA537G、HA547G、HA617G、HA627G、HA637G | 8 3/8 | 212.7 | HA117、HA127、HA216、HA437、HA447G、HA517G、HA527G、HA537G、HA547G、HA617G、HA627G | 8 1/2 | 215.9 | HA117、HA126、HAT127、HA217、HA417、HA437、HA447G、HA517G、HAS517G、HA527G、HA537G、HAS537G、HA547G、HA617G、HA637G | 8 3/4 | 222.3 | HA116、HA117、HA127、HA217、HA437、HA447G、HA517G、HA527G、HA537G、HA547G、HA617G、HA627G、HA637G | 9 1/2 | 241.3 | HA127、HA417、HA437、HA437、HA517G、HA537G、HA617G | 6 5/8 | 37.9~43.3 | 9 5/8 | 244.5 | HA537G | 9 7/8 | 250.8 | HA116、HA117、HA126、HA127、HA417、HA427、HA437、HA517G、HA537G、HA547G、HA617G、HA627G、HA737G | 10 1/2 | 266.7 | HA417GL | 10 5/8 | 269.9 | HA126、HAT127G、HA417、HAT417G、HA517G | 11 | 279.4 | HAT127G、HAT417G、HA527GY、HA547GY | 12 | 304.8 | HA316G、HA517G、HA527G、HA537G、 | 12 1/4 | 311.2 | HA116、HA117、HAT117G、HA127、HAT127G、HA417、HA437、HA447G、HA517G、HAS517G、HA527G、HA537G、HAS537G、HA547G、HA617G、HA637G |

Note: Bit sizes and types that are not shown in above table can be customized according to specific drilling requirements. For insert bit, special T and S features and optional features H, Y, L, G and C can be added. For steel tooth bit, optional features T, L, G and C can be added to the bit. D. Recommended operating parameters of HA series roller cone bits Bit type | Normal WOB

kN/mm

(bit dia.) | Rotary Speed (rpm) | Cutting structure | Applicable formation | HA116 | 0.35~0.90 | 150~80 | Hardfaced tooth surface and gage, high cutter exposure | Very soft with low compressive strength and high drillability, such as soft shale, clay and salt bed, etc. | HA117 | Hardfaced tooth surface and gage, high cutter exposure and the gage fitted with compacts | HA126 | 0.35~1.00 | 150~70 | Hardfaced tooth surface and gage, high cutter exposure | Soft with low compressive strength and high drillability, such as shale, clay, salt bed and soft limestone, etc. | HA127 | Hardfaced tooth surface and gage, high cutter exposure and the gage fitted with compacts | HA136 | 0.35~1.05 | 120~60 | Hardfaced tooth surface and gage | Soft to medium soft with low compressive strength or soft with harder stringers, such hard gypsolyte, soft limestone and sandstone, etc. | HA137 | Hardfaced tooth surface and gage, the gage fitted with compacts | HA216 | 0.50~1.20 | 90~50 | Hardfaced gage and all tooth surfaces | Medium hard with relatively higher compressive strength and hard stringers, such as shale, sandstone and limestone, etc. | HA217 | 0.50~1.20 | 100~50 | Hardfaced gage and all tooth surfaces, and the gage fitted with compacts for enhanced gage protection | HA417 | 0.35~0.90 | 140~70 | Large dia. offset crested scoop compacts in inner row, wedge compacts in outer row | Very soft with low compressive strength and high drillability, such as shale, clay, sandstone and conglomerate, etc. | HA437 | 0.35~0.95 | 140~60 | Large dia. offset crested scoop compacts in inner row, wedge compacts in outer row | Very soft with low compressive strength and high drillability, such as shale, clay, sandstone and conglomerate, etc. | HA447G | 0.35~1.00 | 140~60 | Conical compacts in inner row, wedge compacts in outer row, and with added number of compacts rows | Soft with low compressive strength and high drillability, such as shale, clay, sandstone, soft limestone, salt bed and gypsolyte, etc. | HA517 | 0.35~1.05 | 120~50 | Large dia. offset crested scoop compacts in inner row, wedge compacts in outer row | Soft with low compressive strength and high drillability, such as shale, clay, sandstone and soft limestone, etc. | HA527G | 0.35~1.05 | 120~50 | Conical and conical scoop compacts in inner row, wedge compacts in outer row and with added number of compacts | Soft with low compressive strength, such as shale, clay, sandstone, soft limestone, salt bed and hard gypsolyte, etc. | HA537G | 0.50~1.05 | 110~40 | Offset crested scoop compacts in inner row, wedge compacts in outer row and inequable spaced compacts arrangement | Medium soft with low compressive strength and harder abrasive stringers, such as hard shale, hard gypsolyte, soft limestone, sandstone and dolomite with stringers, etc. | HA617G | 0.50~1.05 | 80~40 | Large radius scoop compacts in inner row, wedge compacts in outer row and inequable spaced compacts arrangement | Medium hard with high compressive strength and thick & hard stringers, such as hard shale, limestone, sandstone and dolomite, etc. | HA637G | 0.70~1.20 | 70~40 | Large radius scoop compacts in inner row, spherical compacts in outer row | Medium hard with high compressive strength and high abrasiveness, such as limestone, dolomite, sandstone and chert, etc. |

Note: The upper limits of WOB and RPM recommended in above table should not be used simultaneously. Series codes of tricone bits: | Serial No. | Main features of the bearing and seal | Standard series | T (Special gage protection) | 1 | Rubber O ring sealed journal bearing | H | HT | 2 | Rubber O ring sealed improved journal bearing | HA | HAT | 3 | Metal rings sealed journal bearing | HJ | HJT | 4 | Rubber O ring sealed roller bearing | G | GT |

Additional features: | explanation of letter | C | Center jet | L | L-pads | E | Extended nozzle | D | Diamond guage protection | G | Guage protection | SP | Horizontal well |

Tricone Bit Characteristics: | High ROP | Safety and reliability | Extended bearing life | Superior pricing |

|