|

API11B Polished Rod

Design to be used with moderate to heavy loads in

non-corrosive or effectively inhibited wells. The

polish rod is using (AISI 4130) Mod steel to

manufacture.

Mechanical Properties

|

Ultimate Tensile Strength, PSI |

95,000~160,000 |

|

(MPa) |

( 655)-(1,103) |

|

Rod Size, OD |

11/8″;

11/4″;

11/2″ |

|

(mm) |

(28.6);(31.8);(38.1) |

|

Rod Length |

8ft~36ft |

Hot Treatment

Quenching; Temper

Sinker bar

The sinker bar

offered two grades to customers: grade 1 (carbon) and 2

(alloy) and the

available sizes are

1 1/4”, 1 1/2”, 1 3/8”, 1 5/8”, 1 3/4”.

Advantageous of using sinker bar:

Create constant tension in the rod string when the

sinker bar placed at bottom of the rod string.

Eliminates compression on the rod string ,reduce the

amount of fatigue failures and the chances of buckling.

Reduction in rod and tubing wear if including sinker bar

in the rod string.

SUCKER ROD STRIPPER

SHINEQUIP’s adjustable Sucker Rod Strippers remove oil

and paraffin from virtually any size rod or piping as

they are being pulled. That stripping action provides a

clean and safe work environment which saves time and

money during lifting operations.Regular use of Sucker

Rod Strippers will provide you with a cleaner, safer

work environment. By stripping oil and paraffin from

virtually any size rod or piping, our Sucker Rod

Strippers will reduce accidents at your well site.SHINEQUIP

sucker Rod Stripper with a pre-installed rod table and

it is made of durable

ductile iron. Its 9-1/2 inch high body has a minimum

bore of 2-9/16 inches and an outside diameter thread

size of 3-1/2 inches.

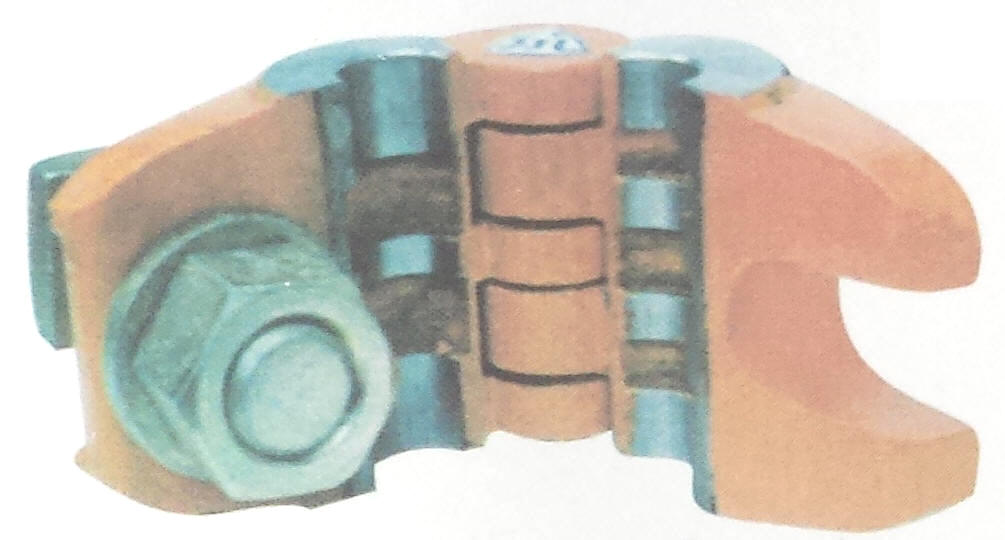

API11B

STANDARD POLISHED ROD CLAMP

Our polished rod clamps adopts the technology of precision casting

and specialized heat treatment to make sure each parts

function well. After repeated tensile load tests and

parameters adjustments, the product complies with the

standard requirements strictly.

Operation Manual for No-indentation polished rod clamp

1. The nominal diameter of polished rod rated

center bore should be the same as that of matching

polished rod clamp.

2. The rated working load for polished rod clamp

should be more than or equal to the needed polished rod

load.

3. Before using, clean polished rod inner bore and

oil stains on polished rod surface to guarantee that the

surface is bright and clean.

4. During installation, polished rod clamp lower

end should be tightly close to pumping unit carrier bar

to avoid impacting when started.

5. If the viscosity of crude oil in oil well is too

big, polished rod lagging down and occurs impacting

phenomenon, our suggestion is to change bigger working

load or use two polished rod clamp in the same type, the

same working load together to increase working load. The

two polished rod clamp ends should be closely tight when

installation.

6. Two bolts should be fastened evenly for the

two-bolt polished rod clamp.

7. Polished rod clamp bolt makeup torque

WL18200 tyoe bolt makeup torque 1977N.m

WL16000 type bolt makeup torque 1545N.m

WL12000 type bolt makeup torque 3200N.m

8. Executive standard API SPEC 11B

Model WL12000 single bolt clamp

|

Model |

Load |

Weight |

|

22mm |

78.5kN(8010kgs) |

5.6kg |

|

25mm |

100kN(10200kgs |

5.5kg |

|

25.4mm(1in) |

100kN(10200kgs) |

5.5kg |

|

28mm |

118kN(12040kgs) |

5.5kg |

|

28.6mm(1

1/8in) |

118kN(12040kgs) |

5.5kg |

Model WL16000 two bolt clamp

|

Model |

Load |

Weight |

|

25mm |

118kN(12040kgs) |

7.3kg |

|

25.4mm(1

in) |

118kN(12040kgs |

7.3kg |

|

28mm |

157kN(16020kgs) |

7.2kg |

|

28.6mm(11/8in) |

157kN(16020kgs) |

7.2kg |

|

31.8mm(11/4in) |

157kN(16020kgs) |

7.1kg |

|

32mm |

157kN(16020kgs) |

7.1kg |

Model WL18100 two bolt clamp

|

Model |

Load |

Weight |

|

31.8mm(11/4in) |

178kN(18160kgs) |

10.35kg |

|

32mm |

178kN(18160kgs) |

10.35kg |

|

38.1mm(lin)(11/2in) |

178kN(18160kgs) |

10.35kg |

Model WRL40000 three bolt clamp

|

Model |

Load |

Weight |

|

31.8mm(11/4in) |

178kN(18160kgs) |

11kg |

|

32mm |

178kN(18160kgs) |

11kg |

|

38.1mm(lin)(11/2in) |

178kN(18160kgs) |

11kg |

2500 stuffing box performance parameter

|

Type |

2500 |

|

Max width(mm) |

170 |

|

Max height(mm) |

500 |

|

Max W.P.(Psi) |

5000Psi |

|

Connection type |

thread connection |

|

Rod Dimension(mm) |

7/8”— 1-1/2” |

|

Weight(kg) |

17 |

Rod stuffing box

Suitable Polished Rod OD (in): 11/8″;

11/4″;

11/2″

Well seal without leakage. Easy to replace the packing.

Pumping rod rotator

The pumping

rod rotator enables the pumping rod at the very slow

speed to rotate clockwise in up-down movement .On the

one hand it turns the rod’s eccentrically worning into

even circumfernential worning, prolongs the life

expectancy of the rod and prevents the rod from

threading off. Meanwhile it also makes the condition of

the rod to be conformed with as the rod rotates, thus

making the multiple-point-touch between tube and rod

change there on and prolonging the life expectancy of

tube. On the other hand it breaks waxation, thus greatly

alleviating the phenomenon of waxation in well.

Technical parameters of Rod Rotator

|

Specification number |

FP-1 |

FP-2 |

FP-3 |

|

Output torque (N. m) |

836N.m |

836N.m |

632N.m |

|

Load (t) |

25 |

25 |

16 |

|

Open-end hole diameter(m m) |

40 |

40 |

26 |

|

Weight (kg) |

45 |

27 |

20 |

|

Rate (n/d) |

0.5-10 |

0.5-10 |

0.5-10 |

|

Package (inch) |

16.2”*11.3”*11.5” |

16.2”*11.3”*8” |

13.6”*12.3”*6” |

|